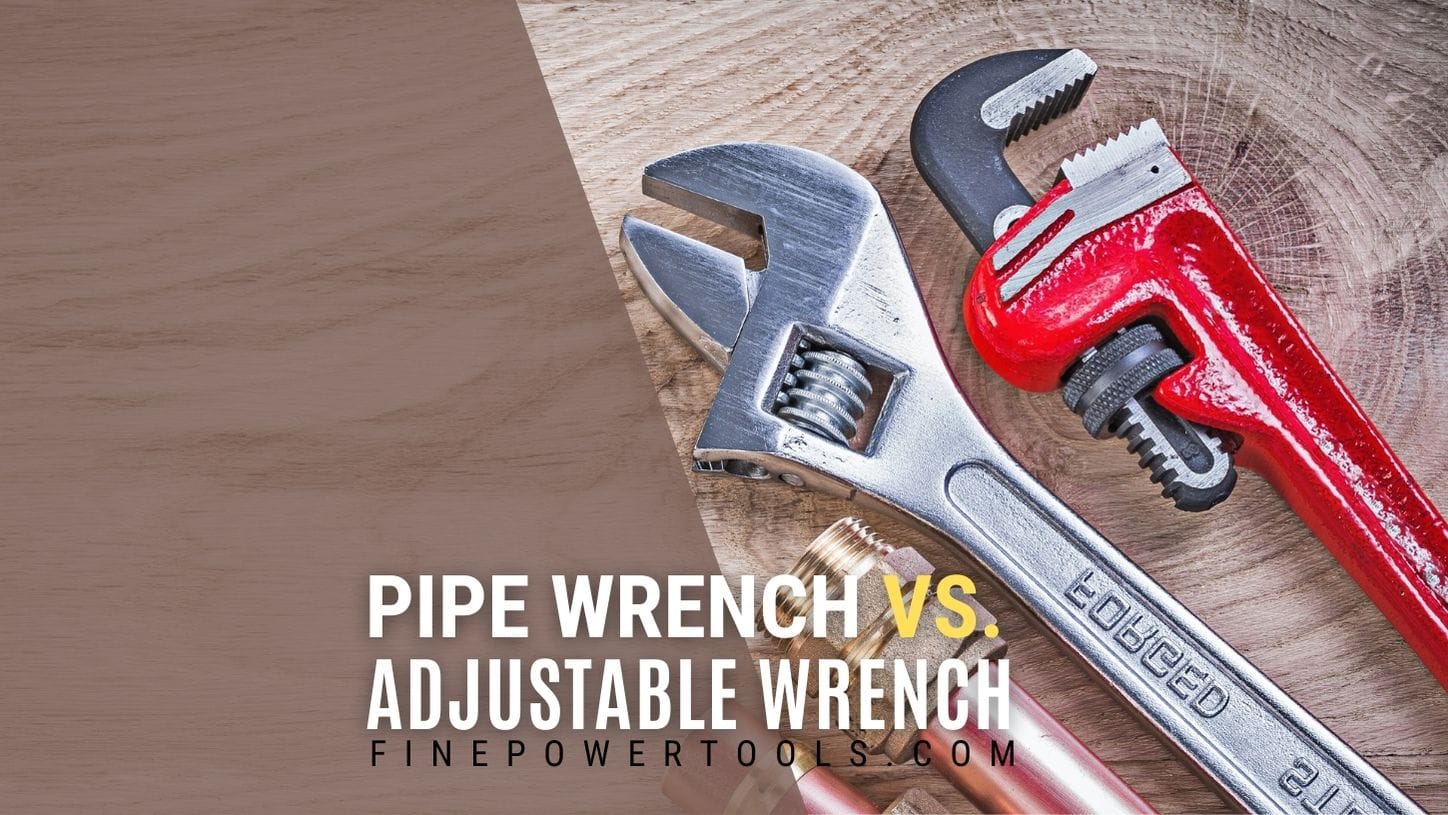

In the vast world of hand tools, the wrench stands as a symbol of utility and precision. Among them, the pipe wrench and the adjustable wrench are two of the most commonly used.

While the basic working mechanism of both these wrenches is similar, they are meant for different purposes.

Let me explain the difference between these two wrenches and their uses.

Key Takeaways

- Both the pipe wrench and the adjustable wrench operate on a similar principle: they have a fixed jaw and an adjustable jaw controlled by a thumb screw.

- The defining difference lies in the jaw design. A pipe wrench features serrated jaws designed to grip round pipes, which can mar the finish of bolts or fittings. In contrast, an adjustable wrench has smooth, flat jaws crafted to avoid damaging nuts or bolts.

- The pipe wrench can securely grip round surfaces, whereas the adjustable wrench requires two parallel flat surfaces for a proper grip.

What is a Pipe Wrench?

As the name suggests, this wrench is specifically designed for pipes.

The pipe wrench consists of two jaws with serrated surfaces for gripping. The top jaw adjusts using a screw to lock it into the shape of the pipe.

Despite the appearance of the serrated surface of the jaws, the wrench will only grip in one direction. This unique design ensures a firmer hold, preventing slipping when torque is applied, especially in the opposite direction.

This also allows for easy repositioning for subsequent turns (like a rachet effect) when turning pipe fittings.

How to Use a Pipe Wrench?

- To properly use a pipe wrench, you start by opening the mouth until it is wider than the object you will be working on.

- Ideally, the pipe should be centered within the jaws before you tighten them.

- Next, turn the thumb screw so that the screw tightens the jaws until they fit firmly around the pipe.

- Once in place, you can push or pull the pipe wrench in the direction you want the pipe to go. This can mean either tightening or loosening the pipe fitting.

Remember to wear gloves when using the pipe wrench. This protects your hands from potential cuts caused by the serrated jaws and provides a better grip, mitigating the risks associated with the high torque and any sharp burrs or edges on the pipe.

Also, if you want to prevent marring or scratching the surface of the pipe, consider placing a cloth between the wrench’s jaws and the pipe.

Pipe wrenches are commonly used in plumbing and construction, but their versatility doesn’t stop there. See the wide range of other applications here.

Like the pipe wrench, the adjustable wrench is arguably one of the most common wrenches you might have come across.

What is an Adjustable Wrench?

This is an open-ended wrench that works on a similar principle to a pipe wrench. However, the closing and opening of the jaws are parallel to the handle.

Adjustable wrenches or spanners come in a variety of sizes. Though many are compact and ideal for smaller projects, such as tightening or loosening bolts, they can also be found in larger sizes suitable for bigger tasks.

How to Use an Adjustable Wrench?

The adjustable wrench operates in the same manner as a pipe wrench.

- You open the jaws wide enough to fit around the bolt.

- Then, you move the adjustable jaw using the thumbscrew.

- Once the jaws hold the bolt head firmly, you can either tighten or loosen the bolt or object.

With its open mouth, the wrench can be adjusted to fit objects as wide as the jaws allow. For a tighter grip on the bolt, adjust the jaws until they fit firmly on the bolt first, remove, and tighten just a little more before returning to the bolt so that it just slips on.

Key Difference in Jaw Design

| Pipe Wrench | Adjustable Wrench |

| Angled Jaws: The jaws of a pipe wrench are set at a slight angle relative to the handle.

This design is essential for the wrench to grip rounded surfaces like pipes effectively. |

Parallel Jaws: The jaws of an adjustable wrench are parallel to each other.

This makes them suitable for gripping flat surfaces on opposite sides, such as the flats of a nut or bolt. |

| Serrated Jaws: The jaws of a pipe wrench are serrated or toothed. This is to provide a better grip on round objects like pipes.

However, this feature can also mar or damage the surface that it’s gripping. |

Smooth Jaws: The jaws of an adjustable wrench are smooth (similar to a monkey wrench) and designed to prevent damage to the surfaces of bolts, nuts, or other fixtures they grip.

This is especially beneficial when working with softer metals and finished surfaces. |

When to Use an Adjustable Wrench vs. Pipe Wrench

- Adjustable Wrench: Any small bolt is perfect for the adjustable wrench. It is designed to turn smaller bolts and screws so they can be loosened or tightened if desired.

This wrench can be used on a wide variety of items, including small pipes and fittings. - Pipe Wrench: The pipe wrench is used on larger objects such as pipes and drains. The leverage gained can provide more force to tightening or loosening pipe fittings.

However, the large size of the wrench may make it unsuitable for small, delicate objects or pipes in tight spaces.

While an adjustable wrench can sometimes be used on pipes, caution is advised. Its smooth jaws, designed primarily for nuts and bolts, can potentially round off the edges of a pipe or fitting.