Torque and RPM go hand in hand; however, this relationship can be difficult to understand.

In this article, I will show you how these variables relate depending on the tool’s design, intended use, and construction, which comes in handy when reading tools’ specs or comparing different models.

In previous articles, we have extensively discussed torque and its implications, but let’s refresh what torque is and how it relates to power tools.

Torque Explained

Torque is the measure of the turning force on an object, such as a bolt or a flywheel. It’s what you feel when you turn a wrench or twist a knob—the ‘twist power’ that causes rotation.

Now, let’s compare this rotational force to its straight-line counterpart: linear force.

What is Linear Force?

Suppose you want to move a box from point A to B. You have to push it, applying a linear force. The force you must apply is given by the mass of the object multiplied by the desired acceleration rate:

F = ma

Where,

F: Force in lbf (pound-force) or N (Newtons), depending on the measuring system.

m: Mass (Expressed in pounds or kilograms)

a: Acceleration (expressed in ft/s² or m/s² depending on the measuring system)

For example, let’s suppose you want to move a 20-pound box at a rate of 2ft/s²:

F = 20 lb * 2 ft/s²

F = 40lbf

Rotational Force

Now, suppose you want to screw a bolt using a wrench. Pushing the bolt is useless; you want to make it turn. As you can’t push the bolt to make it turn, you need to apply a rotational force, and that’s what Torque is.

T = r*F

T: Torque in pound-feet (lb-ft) or Newton-meters (Nm)

r: Distance (In this case, it would be the length of the wrench)

F: Force applied to the wrench (in lbf or N)

Imagine you want to fasten a bolt using a 1ft long wrench applying 40 lbf.

T=1ft∗40lbf=40lb−ft

Torque and Rotary Power Tools

Rotary power tools are designed to turn; that’s why they produce a rotational force or Torque.

But it’s important to note that torque is sometimes mistakenly used as a synonym for power while they are two completely different concepts. That’s where RPM and other factors come into play, as you will soon discover.

RPM and Angular Speed

RPM (Revolutions Per Minute) is the most common way to express the speed of an engine, electric motor, or tool. One revolution equals a full 360-degree rotation of the machine’s shaft or main axis. Before diving into how RPM and torque relate, let’s have an insight into angular speed, which expresses how quickly an object rotates around a central axis and is measured in radians per second (rad/s) in concordance with the International System of Units (SI).

1 RPM = 2π radians / 60

So, if you want to calculate the angular speed of a drill turning at 2,000 RPM, you just have to make this simple multiplication (simplifying π to 3.14159)

2,000 * (2π / 60)

2,000 * (6.28318/60) = ~209.439 rad/s

Knowing how to convert RPMs to rad/s is fundamental to understanding the physics behind the relationship between torque and RPM.

Torque vs. RPM Curves in Power Tools’ Motors

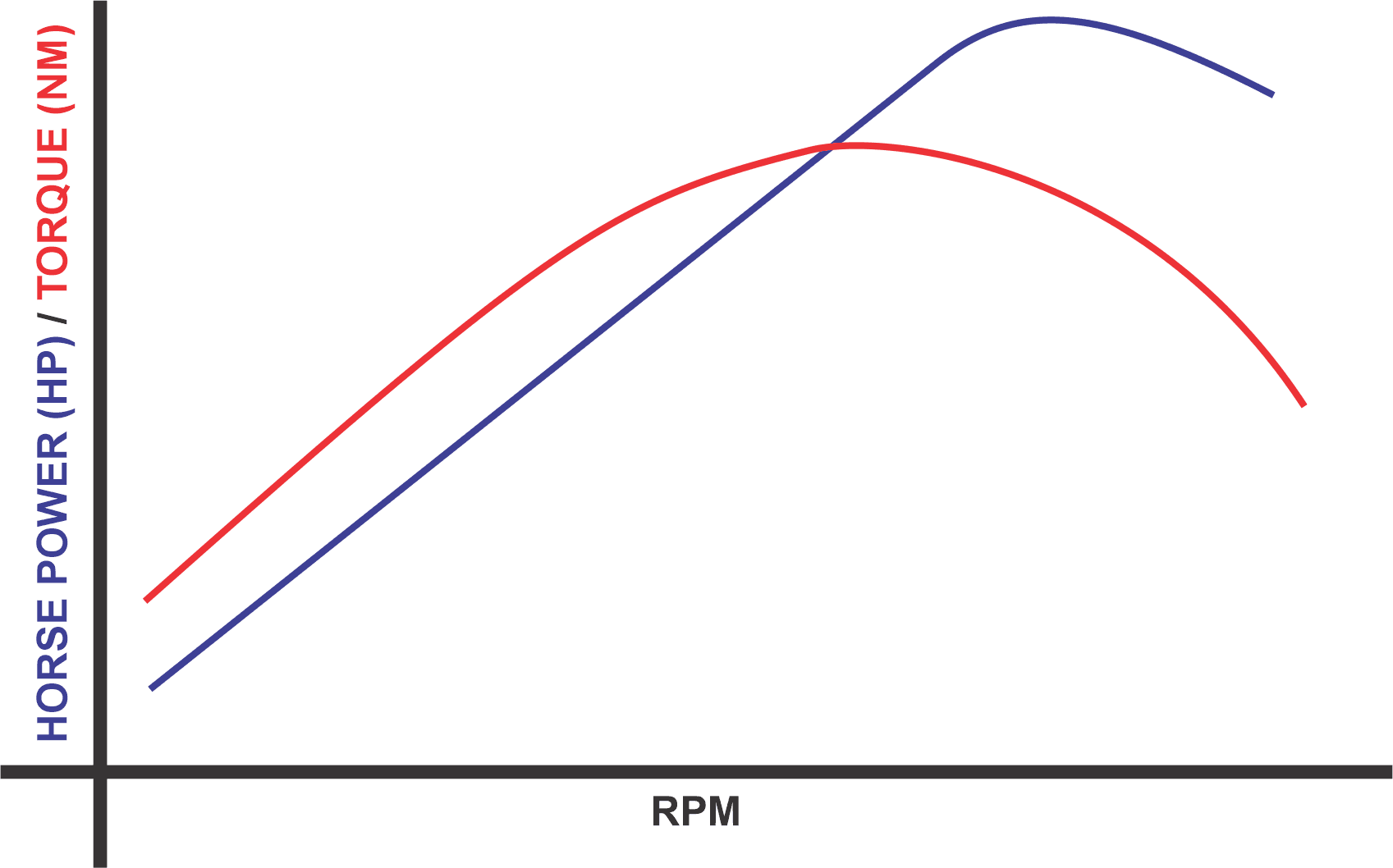

You don’t need to look at an internal combustion engine’s power curve to notice that as RPM goes up, power and torque increase. You can feel it just by driving a vehicle: power builds up as you rev the engine, and so does torque.

Fig: Internal Combustion Engine Torque and Power vs RPM Example

On the other hand, electric power motors’ curves look completely different and seem to go against logic at first sight. When looking at the power curve of a standard motor (with no electronics or complex technology), you will see something similar to the graph below.

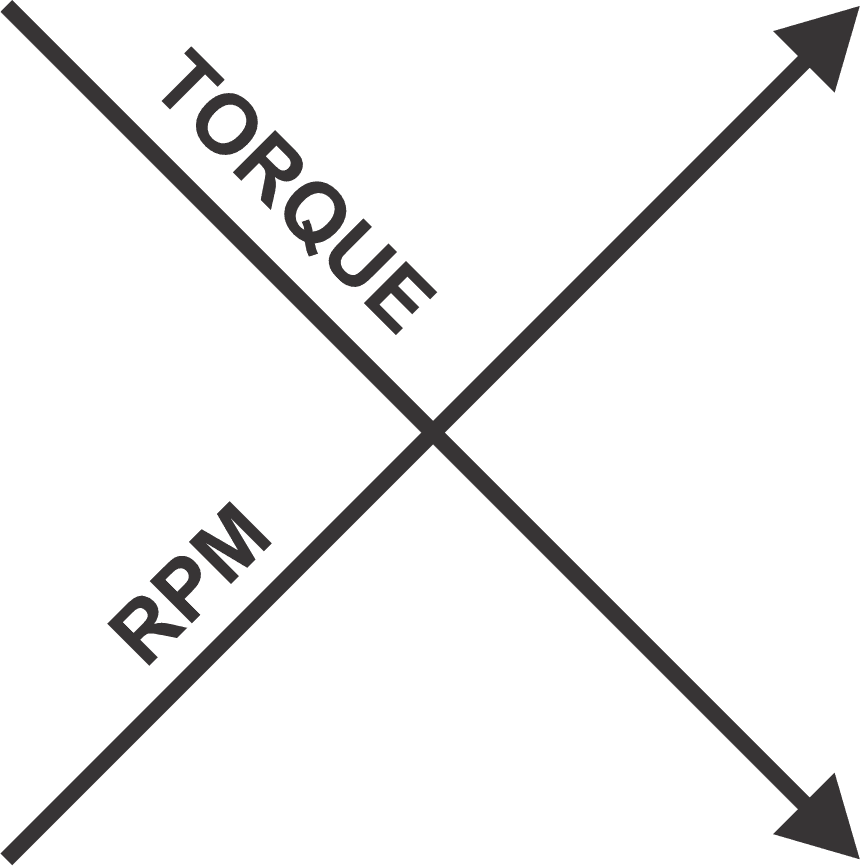

As RPM goes up, torque goes down, and when torque goes up, RPM goes down. When the motor is activated, torque is at its peak and decreases as the RPM increases.

This is because electric motors used in power tools work differently than internal combustion engines or other electric motors. Let’s start with the fact that they don’t produce power but torque and rely on a fixed power source to deliver it.

Electric power tools are powered by an external fixed AC or DC voltage and current and if you disregard external factors such as friction, heat, and others, power remains constant. So, assuming the motor is working in an ideal scenario, torque and speed relate to power in the following way:

P (Constant) = T*ω

P: Power (expressed in Watts)

T: Torque (In lb-ft or Nm, depending on the measuring system)

ω: Angular speed (expressed in rad/s)

Now let’s Imagine an 850W motor that produces a maximum speed of 3,000 RPM or 314 rad/s, then:

850W = T*314 rad/s

T = 850W / 314 rad/s

T= 2.70Nm

From all the above explanations, you can conclude:

- Power is not affected by RPMs because it comes from an external power source.

- The result of the multiplication of angular speed (RPM) by the Torque can never exceed the motor’s power because power is a fixed value.

- Because Torque is the result of power divided by speed, as speed increases, Torque decreases.

- Also, RPM results from dividing power by torque, so as torque increases, the RPMs decreases.

- In this system, Power is not built by RPMs as it happens in other machines, making it mathematically and physically impossible for torque to increase along with RPM.

- As you increase the load, power consumption tends to increase.

Torque vs. RPM Curves in Different Power Tools

Even when all rotary power tools share the same working principle, their torque delivery varies.

Over time, tool designers and engineers use several strategies to control torque and power outputs. This control has increased thanks to the advances in electronics and modern and more efficient engines.

Power Drills

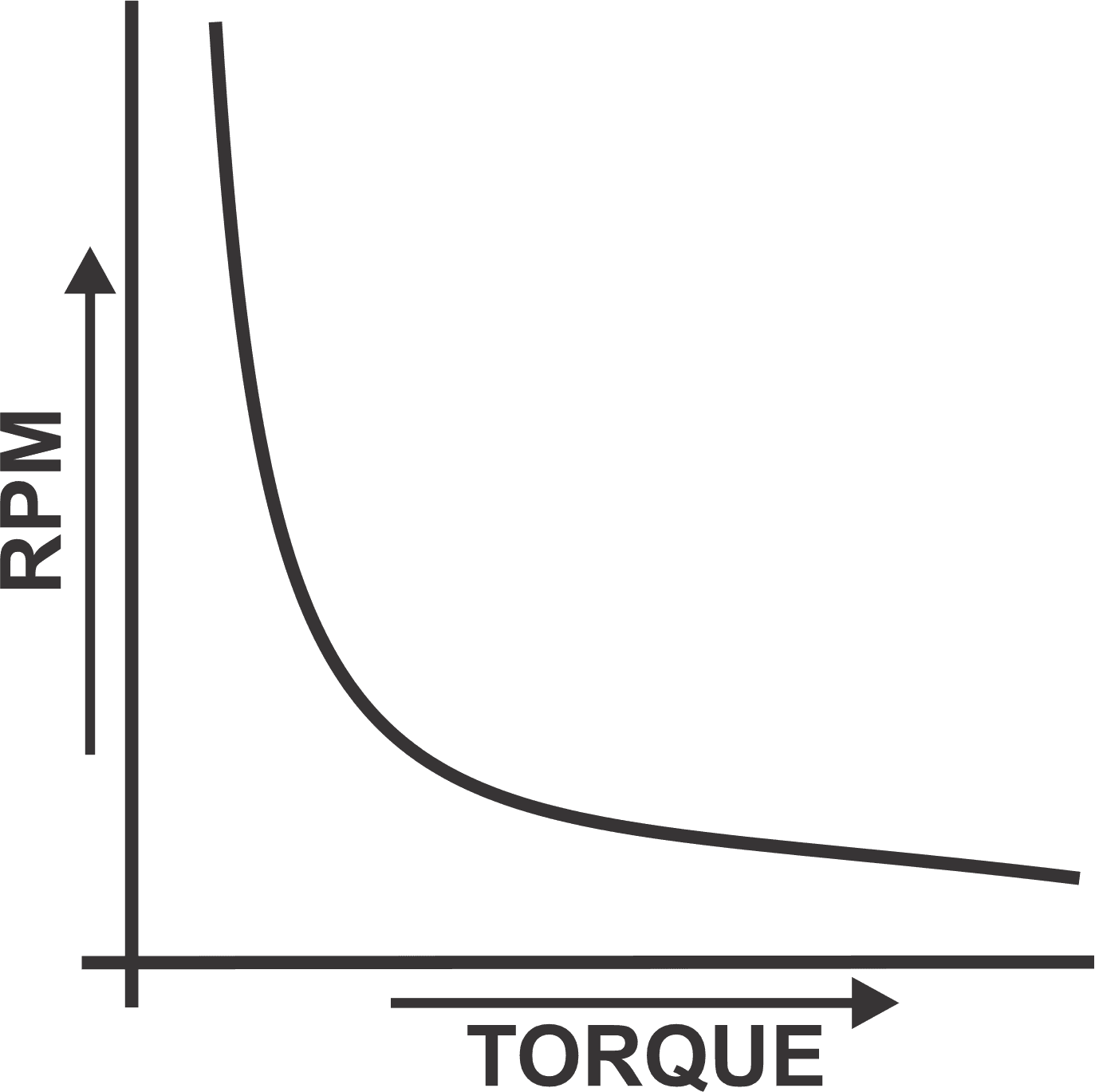

The relationship between torque and RPM in power drills is closer to the relationship of their motors.

Torque and RPM curves are inversely proportional, making hard objects easier to drill at lower speeds. However, by using gears, manufacturers can adjust the power curves to shift the tool’s peak torque to certain RPMs or make the torque curve smoother.

Another resource to increase torque at higher RPMs is to raise the motors’ power. This will result in a higher initial torque; hence, the torque will be significantly bigger at high RPMs.

An electric power drill’s torque can be classified into the following stages:

- Peak or Initial Torque: As soon as the power drill starts spinning, the torque is at its peak value. The motor works with minimal resistance, and the high torque accelerates the main axis.

- Torque Weakening: As the bit comes in contact with an object, the rotational speed tends to slow down, and torque should go up. However, most modern drills have protection systems that reduce torque when necessary to protect the motor and avoid overheating.

- Steady Stage: Once the tip achieves a constant speed, torque stabilizes unless the bit encounters higher resistance.

- End Torque: As RPM reaches its maximum, torque decreases due to the drill’s motor limitations explained previously.

Fig: Typical Torque Curve of a Power Drill.

Impact Wrenches

These tools are designed for applications where high torque levels and speed are crucial, such as fastening or unfastening nuts and bolts.

Impact wrenches simultaneously rotate and apply concussive blows to the workpiece, with the frequency of these impacts measured in Blows Per Minute (BPM). This dual-action—rotation combined with percussion—enables the tool to deliver significantly higher torque at higher RPMs, which is ideal for demanding tasks.

The torque vs. RPM curve of these tools varies depending on the model but looks similar to this:

If you look at impact wrenches’ speed vs torque curves, you will see that the combined torque output looks different compared with the one found at drills. Electric impact wrenches usually feature several modes, and some tools offer advanced features that combine speed and torque selection.

Because of their construction, which relies upon advanced controllers and mechanisms, you can find that most impact wrenches’ torque increases along with the RPM, at least up to a certain point.

Power and Efficiency

A critical aspect to consider alongside torque and RPM is the efficiency of the motor.

While the input power supplied to a tool remains constant, the efficiency with which the motor converts this power into useful work can vary. Efficiency is influenced by several factors, including the operating speed of the tool, the load conditions, and the temperature.

In practical terms, this means that even if a power tool is rated for a certain power level, the actual torque and speed delivered to the load may be less than the theoretical maximum due to inefficiencies.

For example, at high speeds, losses like windage and friction become more significant, potentially reducing the effective torque output.

Conversely, at lower speeds, the motor may operate more efficiently, allowing more of the power to be converted to torque.

When you grasp the power tool’s efficiency curve, it reveals the most productive operating conditions and helps ensure the tool life by using it within its most efficient range.

Final Thoughts

Once you discover that most electric power tools have constant power, the curve of torque and RPM starts making sense.

It’s incredible how electronics, brushless motors, and other technological innovations helped to make rotary power tools more versatile and accurate.

The torque curve of power drills is appropriate for that job because once you have broken the material’s surface, you need speed for a controlled operation. On the other hand, when you need to adjust or lose a fastener, you need a lot of initial torque, but you may also require high torque and speed combined, and that’s where the impact wrenches come in handy.

Understanding these curves is important because they give you a better understanding of your tool so you can use it more effectively. Besides, this information is helpful when navigating through spec sheets to find a tool that suits your needs best.