It pays to use the right tool for the job. This is especially true when it comes to wrenches, of which there are numerous types.

By grasping the fundamental purpose of each variant, you’ll be equipped to select the ideal wrench for any given job.

I’ll explain the most commonly used wrenches in this guide, detailing their functions and potential applications.

1. Open End Wrench

The open-end wrench is one of the most common types of wrenches around. It is certainly one of the most identifiable as a wrench, and it has been in use for centuries.

The wrench has a U-shaped grip on one end that connects to two sides of a fastener, such as a bolt or nut. The wrench is then turned to either tighten or loosen the fastener.

Uses

Open-ended wrenches are mostly used to loosen or tighten bolts or nuts on many different types of items, ranging from small toys to large machinery. The open end allows for easy access, and the slightly bent head creates more opportunities to apply torque to the fastener.

The downside of open-ended wrenches is that they only touch two sides out of six on a hexagonal bolt or nut. This means that they are more likely to slip compared to other types of wrenches, such as the box-end.

2. Box-end Wrench

The box-end wrench is noted for its closed-loop or box appearance. It is designed to fit entirely around the head of the bolt or nut. By surrounding it on all sides, the main advantage is that the box-end wrench offers a better, tighter grip on the nut or bolt.

Because of the grip, the chances of slippage are greatly diminished. This means that stripping the head of the bolt or the nut itself is greatly reduced. This not only reduces potential damage it also means that nuts or bolts that are more securely fastened are easier to loosen.

The same is true for tightening nuts and bolts, which are better performed with a box-end wrench.

The downside is that a box-end wrench does not work in tight places where there is no room for the handle. This limitation is similar to the one faced by open-end and crescent wrenches.

3. Combination Wrench

Instead of having to choose between an open-end and box-end wrench, you can choose both in a single wrench. A combination wrench features an open end on one side and a box-end on the other of the same size. This allows you to choose which one to use for the job at hand.

The combination wrench is quite common and an economical solution compared to purchasing both types of wrenches separately. It is this versatility that provides the main advantage of owning this type of wrench.

The only downside, which is a small one, is that if one end is damaged, you may have to replace the entire wrench rather than using the other side if both sides are the same size. But that is a minor issue at best.

4. Adjustable Wrench (Crescent Wrench)

The adjustable wrench is arguably the most common type of wrench available. The wrench is noted for its adjustable jaw so that it can fit a range of sizes. This means that for many jobs that require the tightening or loosening of nuts or bolts, you only need to carry the adjustable wrench with you.

Sometimes called a crescent wrench, the upside of having this in your toolbox or on your belt is that you only need this wrench for many types of common tightening and loosening jobs. A simple adjustment will help it fit the most common sizes of nuts or bolts.

The downside is that the adjustable wrench does not fit quite as tightly or securely as an open-end or box-end wrench. That means for nuts or bolts that are very tight, the adjustable wrench may slip off. Worse, the slipping may damage the nut or bolt and make it very difficult to remove it with a standard wrench.

5. Socket Wrench

While open-end, box-end, combination, and adjustable wrenches are well-suited for most loosening and tightening tasks, their handles preclude the ability to reach nuts or bolts located in tight spaces. This is where a socket wrench comes into play.

A socket wrench uses removable sockets that are attached to the wrench at a 90-degree angle. The socket is then fitted over the nut or bolt and turned to either tighten or loosen the fastener.

This type of wrench consists of a socket attached to a ratcheting handle, and with its ratcheting mechanism, you can tighten or loosen the fastener without having to reposition the wrench constantly.

Uses

Socket wrenches are most used in automotive maintenance and repair. But it can be used in all situations when a hexagonal nut or bolt needs to be tightened or loosened.

The only downside is organizing and finding the right socket size, which is a little more difficult compared to organizing open or box-ended wrenches. Plus, it is not as convenient as an adjustable wrench.

6. Spanner Wrench

The term spanner wrench is American in origin. In the UK, a spanner means a non-adjustable wrench.

A spanner wrench is distinct in its design. Instead of the typical open or closed-end grip, it features pins or hooks at one or both ends of its handle. These pins or hooks are designed to engage with specific holes or slots present in certain fasteners.

This unique mechanism allows the user to apply torque for tightening or loosening without the risk of slippage that might occur with more conventional wrenches.

The protruding pins or hooks help differentiate the spanner wrench from other wrench types. Apart from its primary use in tightening or loosening, its enhanced grip can also be beneficial when holding items in place, especially if they need to be rotated or turned by other tools.

7. Torque Wrench

A torque wrench is designed to measure and then apply a specific amount of force or torque to a fastener such as a nut or bolt. Unlike standard wrenches that transfer all the force you apply to the fastener, the torque wrench can measure or limit the torque to ensure that the right amount of force is applied.

Common Uses

Torque wrenches are mostly used for assembling automobiles, machinery in factories and assembly plants, and the like. The torque wrench is important in such industries to apply the right amount of force. Too much may strip the fastener, while insufficient torque can cause the nut or bolt to be loose.

You can find the complete list of torque wrench uses here.

The downside is that torque wrenches are only designed to tighten fasteners, not loosen them. You can damage the torque wrench if you try to loosen a frozen bolt or nut. Instead, you must use a breaker bar or impact wrench to remove stubborn fasteners.

Also, the torque wrenches should be recalibrated periodically to ensure accuracy.

8. Flare Nut Wrench

A flare nut wrench has a jaw that partially encircles a nut, offering more contact points than a standard open-end wrench. This wrench is specifically designed for nuts that are attached to tubes, often found in brake, fuel, and HVAC lines.

Unlike the box-end wrench that fully encircles a nut, the flare nut wrench has a narrow opening in its jaw. This opening allows the wrench to fit over the tube, giving it a solid grip on the nut without disturbing the attached tube.

This design minimizes the risk of damaging soft metal flare nuts, which are more prone to damage when using regular open-end wrenches.

These wrenches are mostly used in the assembly and automotive industry for assembly and repairs. You’ll see the flare nut wrench used for brake lines and gas fittings, which have tubes that are connected to a nut or bolt that must be tightened or removed.

While it’s highly effective for its intended purpose, it’s not the best for standard nuts and bolts due to its specialized design. For standard hexagonal fasteners a box wrench or ring spanner works better in most cases.

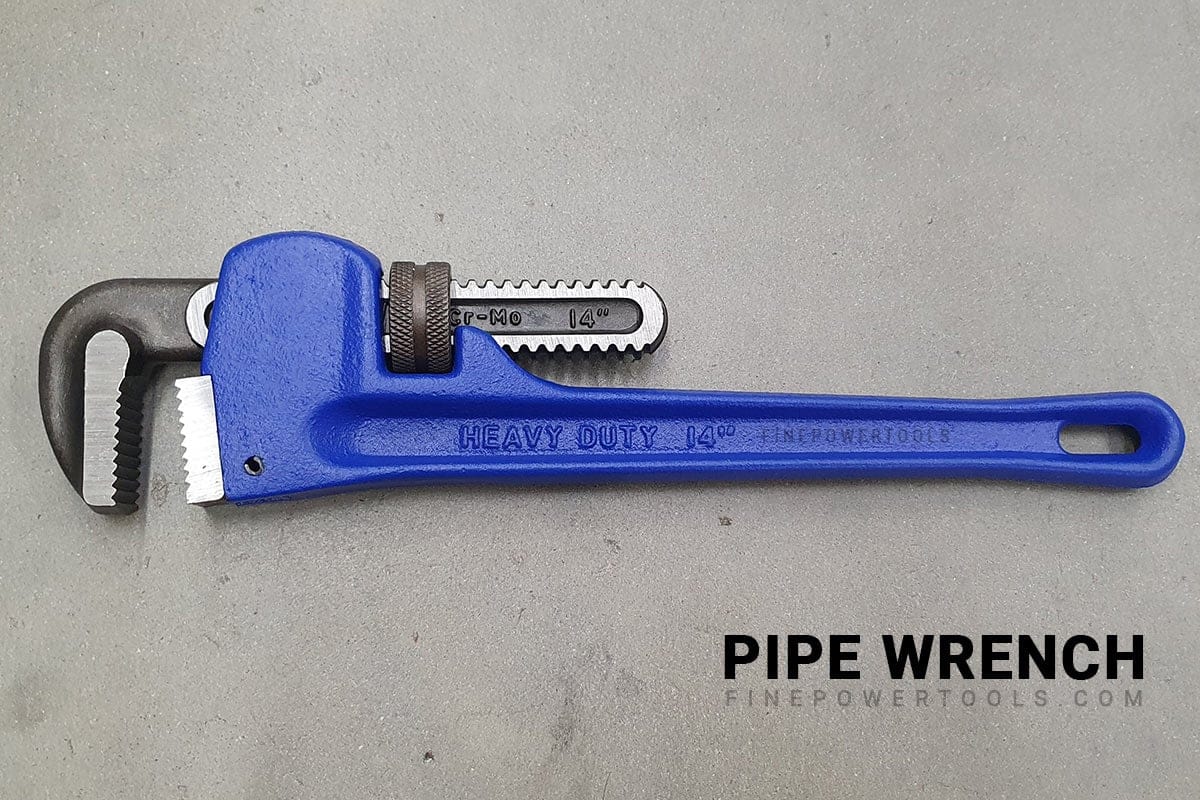

9. Pipe Wrench

Although not as commonly used as adjustable wrenches, the pipe wrench’s unique shape makes it instantly identifiable. However, the pipe wrench itself is not normally used in tightening or loosening nuts and bolts. Instead, as the name implies, it is mostly used on pipes and large plumbing fittings.

The pipe wrench consists of two separate parts connected by an adjustable screw. The serrated jaws are designed to grip around the pipe tightly so that it can be tightened or removed more easily. The pipe wrench itself comes in different sizes, although its adjustable nature means that it can fit a wide range of pipes.

The advantages and disadvantages of the pipe wrench can be found in the serrated jaw used to grip the pipe. While they provide sufficient traction to engage the pipe, they can also leave behind small indentations.

10. Crowfoot Wrench

The crowfoot wrench is a tool that cannot be used on its own. Instead, it must be connected to a ratchet handle, torque wrench, or extension to work. This is essentially the head of an open-end wrench which has a hole at the base to allow it to be connected and operated.

The crowfoot wrench is designed to be used in closed-in spaces that do not allow for a traditional open-end, box-end, combination, or adjustable wrench to be used.

The wrench profile is perpendicular to the head, meaning the handle is attached at a 90-degree angle. This allows for the head or crowfoot to be placed in a tight space. Which also explains the name of the wrench as when it is attached, it looks in some ways like a crow’s foot.

The downside of the crowfoot wrench is that it falls outside its use. Since it is only used in tight spaces, the wrench is far less efficient to use in open spaces that allow for other types of wrenches to be employed.

11. Strap Wrench

The strap wrench is unique in that it consists of a fabric or rubber strap that is tightened around the object. Once in place, the strap wrench can either tighten or remove the item in question without damaging the item itself.

Strap Wrench Uses

The most common use of the strap wrench is to tighten and remove oil filters from engines. The strap wrench allows for proper torque to be applied without damaging the filter itself. Plus, the strap wrench can be used to open lids that are too tight to be opened by hand.

The downside is that a strap wrench is designed for items that are mostly, if not entirely, round. A traditional nut or bolt would be quite difficult to tighten or loosen due to the corners, which will not allow the strap wrench to meet the surface area fully.

12. Chain Wrench

The chain wrench, as the name suggests, consists of a chain used to surround and grip onto larger items. The chain is secured by a handle that is directly connected to the chain. Once in place, the chain wrench can tighten or loosen items in a similar manner as a strap wrench.

The chain wrench is most used in plumbing on pipes that are generally too large for a pipe wrench to be effective. You’ll also find it used in the oil and gas industry along with other fields that use large pipes.

The advantages of the chain wrench are considerable as they can grip round, square, or different-shaped objects without crushing them. Like the strap wrench, they are adjustable and can be used on many different sizes.

The downside is that a chain wrench will leave its mark. This means that if aesthetics is important, something may need to be wrapped around the pipe first before the chain wrench is applied.

13. Allen Wrench (Hex Key)

The Allen wrench (also known as the Allen key or hex key) is shaped like the letter “L” with a hexagonal cross-section. The wrench is designed to drive screws that have a hexagonal socket in the head.

Allen Wrench Uses

You’ll find Allen wrenches most often used for repairing bicycles, assembling furniture, and with some mechanical along with electronic devices. The hexagonal socket has more corners and surface area for the wrench to attach, making tightening and loosening easier and with less chances of stripping.

The downside is that there are several different sizes of hexagonal sockets, so you will need to carry several different sizes of Allen wrenches. Fortunately, you can purchase a set of Allen wrenches which can be carried together easily.

A variation of the hex key is the torx key which has a star shaped drive profile. You can see the difference between hex and torx wrenches here.

There you have it: the most commonly used wrench types.

The above list is not exhaustive; several variations and special wrenches exist.

Regardless of the type, it’s imperative to choose the correct size and design for the job at hand, ensuring efficiency and the protection of fasteners from potential damage.